While entering a business building, laborers and clients hope to stroll upon strong, safe, and clean floors. Normal floor support is intended to keep expressed floors in excellent condition. Be that as it may, even the prized floors will wear out, so, all in all, new floor coatings should be applied. A lot of planning and method goes into an effective coating position. In light of that, the following are 9 hints for floor coating applications for business buildings.

1. Plan In an intelligent way

Besides the undertaker’s extension, the significant contrast between private and business floor coating positions is booking. At the point when a mortgage holder needs another carport floor coating, they can essentially avoid that region for a couple of days. Organizations, then again, should facilitate a few groups to guarantee the legitimate utilization of business floor paint with insignificant functional obstruction. Thus, numerous organizations will intentionally enlist floor workers for hire to work during brief shutdowns or potentially eased back tasks (for example occasions, ends of the week). Any other way, a certain region of the structure should be cut off at given spans. The more thought you put into this preparation, the smoother the work will go, and the better the outcomes you’ll get.

2. Clear and examine the regions being referred to

Whenever you’ve decided when, where, and how your floors will get coated, you should eliminate all gear, furniture, and things from the areas being referred to so they don’t disrupt the general flow. When the floors are open, specialists ought to assess them for things like water harm, shape, pitting, and so on. On the off chance that the signs are obtrusive and serious, the foundational issue should be settled before the floors can be additionally ready for coating.

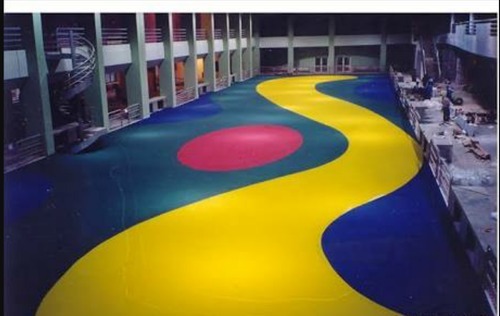

3. Pick your coating

There are many floor coating choices accessible for business buildings. Polyurea concrete floor coatings stay a famous choice, and these coatings must be complex. They have a groundwork and base coat of modern epoxy floor paint. The polyurea coating is an adaptable material that gets dampness and chemicals far from the floor and forestalls breaking. Besides polyurea, you could pick urethane concrete coatings. At Anderson Painting, our experts introduce Penntek polyurea floor coatings for their toughness, flexibility, life span, and stylish allure. At last, your choice will be founded on your spending plan, visual inclinations, and explicit flooring needs.

4. Completely perfect your floors

Regardless of which sort of coating you go with, they can’t be applied if your floors are dirty. The coatings won’t as expected stick to and bond with your floors except if they’re sparkling clean. Cleaning should be possible using force washing or potentially manual scouring.

5. Make fundamental fixes

Not exclusively should your floors be perfect to be appropriately coated – – they should likewise be looking great. Breaks, pits, and compression joints should be filled and streamlined. Abstain from utilizing plastic fix items while filling in your floor’s defects, as these are delicate and coatings don’t stick well to them.

6. Guarantee the appropriate climate

Similarly, as with any artwork cycle, factors like temperature and stickiness can influence results. In this way, working in the appropriate natural conditions is significant. For legitimate polyurea floor coating application, ensure temperatures decrease somewhere in the range of 55 and 90 degrees Fahrenheit and stay away from the application assuming mugginess levels are 85% or more.

7. Apply uniformly and rapidly

Floor coatings can be fussy – – you frequently have a restricted window of time to finish a coat in the wake of pouring it onto the floor. To this end, such tasks are best passed on to the experts who know how to appropriately blend the coating, pour it, carry it out, and the number of coats to apply.

8. Count the coats

More than one coat is frequently needed for coating business floors. With regards to applying Penntek polyurea floors, for example, we apply a base coat, a layer of pieces for surface and pizazz, and a top coat for added sparkle and insurance.

9. Allow it to dry

Each coat should be abandoned for a given window of time before continuing toward the following one. Moreover, the completed outcomes should be relieved and dried before anybody can go to the recently completed floors. Industrial Floor Coating It takes significantly longer for the floors to tolerate vehicles and large equipment. While these times shift, 18-24 hours are normally expected before individuals can securely step upon the floors, an additional 24 hours ought to pass before items can be put on them, and one more little while ought to go by before vehicles are permitted. Neglecting to give your coatings the essential fix times can bring about significant issues in the short-and long haul.